After finishing off my case mod (see sig), I found that stopping my modder's reflex is a little harder than I expected it would be. Long story short, I figured I'd use some of the leftover parts from my case, to make one of those fancy glowing mousepads.

Now, you've all seen them, and mine's nothing different or special. Nonetheless, I feel I should contribute to the Mod Guides section with a pictorial guide.

First of all, it's important to know that I'll be using the router heavily throughout this project. Most people would suggest a dremel or jigsaw for doing this sortof thing, but if you have a router, now's a great time to use it. Using tools like the router and tablesaw can bring a much higher level of accuracy to the project, and make you feel better about your work.

Anyways, start by cutting out a plywood mockup of the mousepad, whatever dimensions you like (I used 8.5*10", since it's about the biggest that could fit on my desk. I'd suggest one a little higher)

Aim for a high level of precision, because the outcome of the pad depends on it

---

Next, cut out (using any tool) an oversized piece of plexi (the thicker the better)

---

Using countersinking wood screws, attach the plywood mockup to a workbench or another, bigger piece of plywood. Then, drill two holes and fit yet another two countersinking wood screws through them, and screw the plexi to the plywood mockup. Clamps would be inconvenient at this point, because it's easiest to do the cutout all at once, and the clamps wouldn't allow that (they'd block the router, and have to be periodically moved)

---

As you can see, we'll be using a standard router, with a 1/2 trim bit. The roller bearing keeps the movement of the blade exactly aligned with the plywood mockup. This allows us to create a perfect duplicate. Another advantage is that the router will usually leave you with a very nice looking edge, requiring little to no finish work

---

Begin cutting, making sure to follow along the path the board makes, and maintain a reletivly fast feed rate. Going too slow causes melting, because the blade isn't so much cutting the material, but rather chipping away at it.

---

Even thougn the cut is complete, we're going to leave the plexi attached to the guide just a little longer. It makes it easier to do finish sanding.

Now, most people would be happy with a sanding block and a lot of time. Not me, however. Today we'll be using a belt sander to finish up the edges and make them all pretty.

Simply follow along the wooden guide with the belt sander turned sideways. The wood should stop you from removing more plexi than necessary.

Since the belt sander's paper may be fairly coarse, follow up with 600 and then 1000 grit wetordry sandpaper. It takes a while, but you get the edges to an almost see-thru level

---

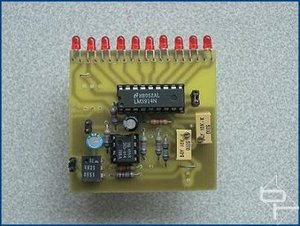

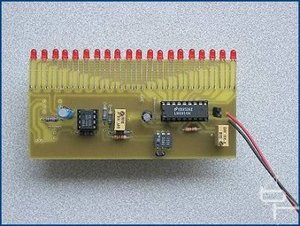

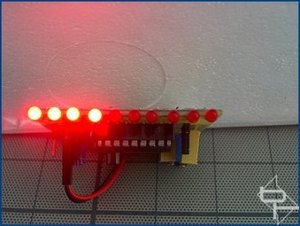

Time for the LEDs. I'll be using 5 superbright reds that I got from an LED cluster at Wal-Mart. You could use blue or whatever if you so desire.

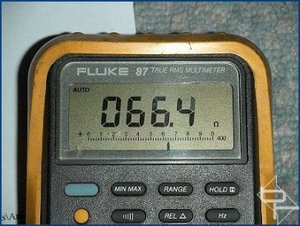

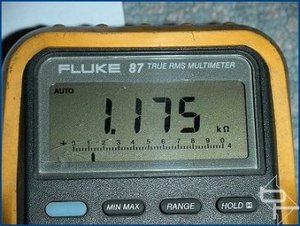

First of all, find an un-used wall-wart and figure out the voltage it puts out. Then use Bit-Tech's own LED calculator to figure out the required resistor

http://www.bit-tech.net/article/68/

---

The plexi I used wasn't too thick (only 3mm) it was necessary to trim down the LEDs. You could do it the safe and patient way and use a file or sheet of sandpaper, but I won't cover that. Instead, I'll show you the magic of the bench grinder. It managed to take the LEDs down to size in a few seconds

---

Next up, we need to make grooves or channels for the wiring to fit through. Once again, we'll turn to our friend, the router for it's assistance. You can't really tell in the picture, but I carefully set the depth of cut so it's about 2mm deep. That way, I can safely cut a 2mm groove in the plexi, and use the other 1mm for support.

At this point I should mention that to mount the LEDs, I drilled 3/8" holes. Honest to goodness holes. Don't worry, they can't even be detected once the surface goes on.

---

A film can is used to house the switchs and wiring. This holds many advantages, such as preventing electric shocks, and preventing 'fallapart'

---

Finally, the mouse tracking surface was from an old school book. I can't really describe the material or give it a name. It was hard, yet bendy. It is also quite low in the friction department, and it lets my mouse glide around freely. It also tracks very well in the optical department. I cut it out so that it was 1cm inset on every edge, and attached it with double sided carpet tape.

---

Finally, the result:

Light on ^^

Light off ^^

Hope this was semi-easy to follow and gave an even clearer understanding and insight into the process of making a mouse pad

Goth is Back, Goth is Good, Goth is the Way! Mouse, Mousepad and Goth Keyboard.

Goth is Back, Goth is Good, Goth is the Way! Mouse, Mousepad and Goth Keyboard.